Railways expand rolling stocks asset life

Railways move to stretch rolling stocks life cycle

Indian Railways is moving fast to widen residual life of its conventional rolling stocks. Taking cue, vendors and service providers are going extra lengths towards product development and support services. Railways Review takes a look.

Indian Railways, continues to adapt cost competitive, yet qualitative, and reliable solutions. Demand are also for products those are easy to operate and maintain for higher asset availability.

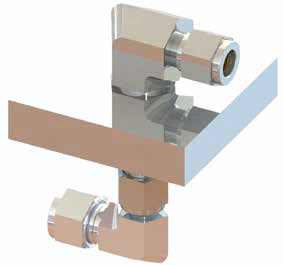

Across frame connectors are easy to fit

Moving towards delivering higher reliability and enhanced product support, brake piping connectors solutions major, Fluid Controls Private Limited is offering fitment installation and product support guarantee for its solutions. “We are offering complete service guarantee for our brake piping circuits and connectors to the Indian Railways. Going by our tagline, the Railways will have to just ‘fit and forget’ as the entire maintenance of the circuits and connectors will be undertaken by us across the lifecycle of the locomotives. This would be through its intermediate and periodic overhaul schedules. We will be also rendering newer installation training support to the Railways” says, Dr. Tansen Chaudhari, Chief Operating Officer, Fluid Controls Private Limited. Installation and service support will be provided by the company both for the conventional and three phase locomotives.

Delivering newer solutions to improve the reliability of its piping circuits, Fluid Controls, has introduced Across Frame Connectors. Sharing details, Dr. Chaudhari says, “The Across frame connectors are custom-designed double ferrule combination fittings with a bulkhead application at one end and a swiveling action at the other, and are used to connect pipelines separated by a panel, such as connections between the shell and bogie. The swiveling action ensures that these connectors can be installed at any orientation, and the bulkhead connection allows the h e i g h t of fittings to be adjusted to the tubing. Across frame connectors can also be used to join tubing of different material and the use of washers ensures vibration resistant joints. Across Frame Connectors offer easy installation and eliminate welding processes. End connections of these connectors are tested and validated to ASTM F1387 standards.”

Adding value engineering Jainex Limited, has developed brake panel for WCAM2 series of electric locomotives overhauled by Bhusawal Workshop. “Since the locomotives were having less residual life, Bhusawal workshop, decided to economize the cost of the brake panels. Based on our engineering expertise for installation of piping circuits and connectors, we designed and developed the panels with complete fabrication done at the workshop itself. This was followed in tandem by creation of space in the engine room behind the driver’s cab and installation of the brake panel with complete mild steel piping work done.” Says Mr. Rahul Dugar, Director, (Railway Business)- Jainex Limited.

Adding value engineering Jainex Limited, has developed brake panel for WCAM2 series of electric locomotives overhauled by Bhusawal Workshop. “Since the locomotives were having less residual life, Bhusawal workshop, decided to economize the cost of the brake panels. Based on our engineering expertise for installation of piping circuits and connectors, we designed and developed the panels with complete fabrication done at the workshop itself. This was followed in tandem by creation of space in the engine room behind the driver’s cab and installation of the brake panel with complete mild steel piping work done.” Says Mr. Rahul Dugar, Director, (Railway Business)- Jainex Limited.

He adds, “Our designed brake panel, featuring rudimentary technology is in contrast to electro-pneumatic system offered by Knorr and Faivley. Our panels have all the valves mounted on the single panel. This has significantly cut down the number of joints. The single panel as a result will drastically curtail the maintenance cost of the pneumatic system in the locomotive.” The design and installation of the brake panels was done by Jainex in WCAM2 locos numbering: 21865, 21861, 21868, 21867, 21874. Having successfully completed the design and installation

work in the five locomotives, Jainex is presently executing the project of panel installation in loco number 21869 at the workshop.

Oxyweld has introduced newer welding solutions based on cold metal transfer technology from Froneus of Austria. It has supplied two sets to Integral Coach Factory for carrying out welding of the side and end wall of the LHB coaches. Sharing details of the solutions, Mr. Vishal Dugar, Director, Oxyweld says, “This is an intelligent welding technology, which will drastically reduce unevenness on the surface. The welding technology works on sensing the signals. Based on this it synchronizes fast the current and the voltage to carry out the welding job.” Oxyweld which is the exclusive distributor of cold metal welding technology from Froneus in India will support the units.

Oxyweld has introduced newer welding solutions based on cold metal transfer technology from Froneus of Austria. It has supplied two sets to Integral Coach Factory for carrying out welding of the side and end wall of the LHB coaches. Sharing details of the solutions, Mr. Vishal Dugar, Director, Oxyweld says, “This is an intelligent welding technology, which will drastically reduce unevenness on the surface. The welding technology works on sensing the signals. Based on this it synchronizes fast the current and the voltage to carry out the welding job.” Oxyweld which is the exclusive distributor of cold metal welding technology from Froneus in India will support the units.

Looking to address the issue of fire protection on railway rolling stocks, and track systems, Fogtec Fire Protection Pvt ltd. According to Mr. Manprit Singh Baweja – Regional Manager – APAC, Fogtec Fire Protection Pvt. Ltd, “Our fully automated fire detection and fighting response solution, can minimize the railway vehicle and allied infrastructure damage, or prevent it entirely from fire. Timely detection of fire and prevention is supported by its rapid activation feature. This curtails the fire to spread out. The fire detection and fighting response solution, ensures high degree of design flexibility while fitment, based on the requirements of the mainline or metro rolling stocks. Support for the flexible fitment based on the design of the rolling stock is provided by our technical team possessing expertise in design, application development as well as international certifications norms for rail vehicles.” He adds, “Fogtec has been developing and supplying active fire protection system solutions for rail-based transport around the globe since many years and is one of the world’s leading suppliers of this technology.”