Shunting advancements galore

Shunting solutions advancements goes extra mile

Given the high present high paucity of wagons, there is a dire necessity of shunting and unloading solutions that deliver faster cycle times. This is so as to make production more efficient with the captive railway’s asset owners. This includes primary steel producers, cement and thermal power plants. For having compressed cycle times, there is a demand for equipment, featuring higher levels of reliability, productivity, and safety.

Premnath Engineering’s rrv shunters are highly suitable to transport men and materials for maintenance of captive railway network of steel, power cement plants.

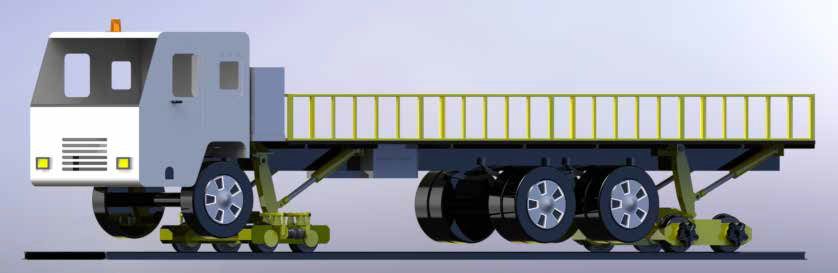

Delhi based, railroad vehicle (RRV) manufacturer, Premnath Engineering Works (PEW) has developed an rrv shunting transportation solution. “The product is based on our well tried and tested rrv platform with attachments for railway overhead electrification. The truckload body in the rrv is mounted on truck chassis between 25-31 tons. It comes with four front and four rear rail wheel arrangement. The equipment features four-wheel drive with heavy duty motors. The rrv shunter, made in-house, under heightened production quality standards is backed by our manufacturing expertise for making the entire hydraulic systems, placement of the gears and hoses, attached to the rail wheelsets for lifting up and bringing down the right truck chassis while working on the rails backed by right pressure.” Mentions, Mr. Vipin Arora, Partner, Premnath Engineering Works.

Delhi based, railroad vehicle (RRV) manufacturer, Premnath Engineering Works (PEW) has developed an rrv shunting transportation solution. “The product is based on our well tried and tested rrv platform with attachments for railway overhead electrification. The truckload body in the rrv is mounted on truck chassis between 25-31 tons. It comes with four front and four rear rail wheel arrangement. The equipment features four-wheel drive with heavy duty motors. The rrv shunter, made in-house, under heightened production quality standards is backed by our manufacturing expertise for making the entire hydraulic systems, placement of the gears and hoses, attached to the rail wheelsets for lifting up and bringing down the right truck chassis while working on the rails backed by right pressure.” Mentions, Mr. Vipin Arora, Partner, Premnath Engineering Works.

Phooltas’s multipurpose rrv units can be used for shunting, accident relief and ferrying work.

Mentioning further he says, “The multipurpose solution, with an ability to shunt up to 300 tons is highly suitable to transport men and materials for maintenance of captive railway network of steel, power cement plants. While the rrv can do towing work, owing to the load body, it can also carry a host of materials to the sidings, marshaling or receiving yards for carrying out emergency track maintenance. The equipment can be used as a derailment relief vehicle as well.” The RRV truck chassis can be delivered based on the customer’s choice including brands like Tata, Ashok Leyland or Bharat Benz.

PEW which offers wide rrv products from its stable provides customized annual maintenance contract support packages along with complete parts support and training. It will be looking to leverage its product support initiatives with the population of its RRV’s rising further. Prominent PEW’s clientele comprises, Larsen & Toubro, Siemens, Alstom India, Kalpataru Power Transmissions and Railtech Infraventure.

Railway overhead electrification and track machine manufacturing major, Phooltas Transrail is offering varied rrv solutions for maintenance of mainline and captive railway network. “Phooltas rrv’s are multipurpose and highly versatile. The same unit can be used for shunting, accident relief, and ferrying work. We introduced the rrv technology in India in 1996. We are the only RDSO approved supplier and have the sole distinction to have supplied RRVs to IR / IIT & RDSO.” Says Mr. Rohitashwaa Kumar Agarwala, MD& CEO, Phooltas Transrail ltd.

Sharing details, he says, “Phooltas has successfully developed four different designs of rrv’s suitable for different base vehicles and applications. All our rrv designs are dual gauge giving gauge selection versatility to the client. These units can be operated from within the driver cabin or standing at the side of the RRV through a remote control.”

Sharing details, he says, “Phooltas has successfully developed four different designs of rrv’s suitable for different base vehicles and applications. All our rrv designs are dual gauge giving gauge selection versatility to the client. These units can be operated from within the driver cabin or standing at the side of the RRV through a remote control.”

Adding further, Mr. Agarwala says, “backed by our sound r&d capabilities, we have developed rrvs for gross vehicle weights from 11 T to 50 T, including SUVs. Our RRVs are available in all gauges or a combination of gauges. We also offer rrv’s with self-propelled rail wheels and RRVs with training / guiding rail wheels.”

Phooltas supports its rrv’s and other products through its offices in Delhi, Kolkata, Mumbai, and Bangalore stocking fast moving spares.

San Engineering and Locomotive co ltd, is looking to expand its business presence for shunting applications in captive railways network through its broad offerings of diesel-hydraulic and diesel-electric shunting locomotives. According to Senior Officials from San Engineering and Locomotive co ltd, “As a leading manufacturer of shunting locomotives, we have an installed base of more than 1000 locomotives. The locos are serving the key industry segments like steel, power, and cement and fertilizer.”

SAN’s diesel hydraulic loco consists of DL 400, DL 450, DL 700, DL 800, DL 1200 DL 1400 DL 2400 and DL 3000 with rated 400, 450, 800 1200 1400 2400 and 3000 horsepower. While the diesel-electric versions consist of DEL 700, DEL 1400, DEL 2000 with rated 700, 1400, 2000 horsepower.

SAN locomotives are available for 1435, 1000, 1067, 1676 mm track gauges come with an option of air-conditioned cabins, creep controls and program logic controls for locomotives control and monitoring.

“The high performance and reliable locomotives are backed by SAN’s superior research and development and manufacturing standards. The locomotives are designed and manufactured in-house using state-of-the-art machining centers. Our manufacturing facilities are located in two plants, Bangalore and Mysore and are equipped with advanced, high precision CNC machines manufacturing very high standard equipment.

“The high performance and reliable locomotives are backed by SAN’s superior research and development and manufacturing standards. The locomotives are designed and manufactured in-house using state-of-the-art machining centers. Our manufacturing facilities are located in two plants, Bangalore and Mysore and are equipped with advanced, high precision CNC machines manufacturing very high standard equipment.

The manufacturing units are supported by the R&D division that leads the SAN development program using solid edge, kiss soft, Nx etc and integrated machine shop and a metrology laboratory.” Informs the officials.

They mention, “SAN shunting locomotives have been engineered for ease of operation. The units, supported by suitable engines for optimum performance are supported by adequate safety features that warn the operating personnel in case of emergency. Optimal arrangement methods of major aggregates is another major attribute of the engines.”

They mention, “SAN shunting locomotives have been engineered for ease of operation. The units, supported by suitable engines for optimum performance are supported by adequate safety features that warn the operating personnel in case of emergency. Optimal arrangement methods of major aggregates is another major attribute of the engines.”

They point out, “consistent traction is delivered by our shunting locomotives by virtue of their best design with horn guides and pivots that can negotiate the curvatures and the challenging industrial environments like thermal power, cement plants”.

The officials say, “To ensure optimum performance of the locomotives, while making them closely indexed for the customer’s requirements, we provide presales support for the selection of shunting locomotives. This is through carrying site assessment on various aspects like track geometry, haulage capacity, speed, and other site conditions to recommend the best suitable model backed by knowledge support for operational training and maintenance.”

San Engineering supports its locomotives, through varied operation and maintenance contracts. Under these, general annual maintenance contracts are undertaken, against which engineer visits are carried as per the pre-agreed schedules. Comprehensive annual maintenance contracts, with the responsibility of parts replacement, is also undertaken. Product support also includes leasing of locomotives.”

San’s product range also includes custom built gearboxes and cardan shafts. According to the officials “The gearboxes have strong footprints across the industries like steel, cement, power, fertilizer for varied applications.” SAN Engineering & Locomotive Co Ltd was established in 1969. Lloyds Engineering has recently supplied, ‘Titan’ rrv to Tata Steel’s Jamshedpur and another to Kalinganagar Steel plant from Trackmobile LLC of US. It is now looking to expanding its market presence for captive railway rakes shunting, based on the competitive attributes of the products.

L&T wagon tippler at Jamshedpur Tata Steel Plant

According to Mr. Subhasis Ghosh, Manager Service, Lloyds Engineering, “The Titan rrv comes with a compact footprint. This makes it easily adaptable with its rrv feature to work in yards with a lesser number of shunting lines thereby cutting down rakes turn round. One of the prime features of the ‘Titan’ rrv is its consistent traction. Trac mobile utilizes time-tested and proven steel wheel technology found on today’s locomotives. Based on the technology, the rail wheel drive train applies constant downward pressure, ensuring safe and reliable contact with the rail wheel. This is even when traveling over unlevel crossings or rail frog keeping the rakes on track. This altogether ensures consistent traction of the rrv while hauling the rakes in dust, dirt and other debris infested industrial environments. For extremely, sharp curves and for longer rakes, Trackmobile through its rrv’s offers an optional extended wide traverse coupler that extends coupler base an additional 6”. Lloyds engineering is the exclusive distributor of Trackmobile rrv solutions in India.

Larsen & Toubro claims to deliver faster and safe unloading though its wagon tipplers through its advanced hydraulics. “Since tippling is a crucial operation, heightened safety is featured in our tipplers through the grippers which hold the wagons firmly during the course of tippling. The advanced sensors in the tipplers automatically control the speed of the units thereby ensuring safe operation.”